BLOG

In the fast-paced world of automotive parts manufacturing, precision, efficiency, and reliability are non-negotiable. Components like engine blocks, transmission housings, and brake system parts often require multi-hole drilling and tapping operations with tight tolerances—especially when working with materials such as aluminum alloys and cast iron. This is where a high-performance Tap Drill Center becomes essential, and Taiwan Winnerstech stands out as one of the best manufacturers in the field.

Why Tap Drill Centers Matter in Automotive Manufacturing

Modern car components are getting more compact, lightweight, and complex. Manufacturers must machine multiple holes with high speed and accuracy while maintaining surface integrity. A Tap Drill Center, specifically designed for high-speed drilling and tapping operations, plays a key role in streamlining production, reducing cycle times, and ensuring consistent part quality.

Introducing Taiwan Winnerstech's High-Efficiency Tap Drill Centers

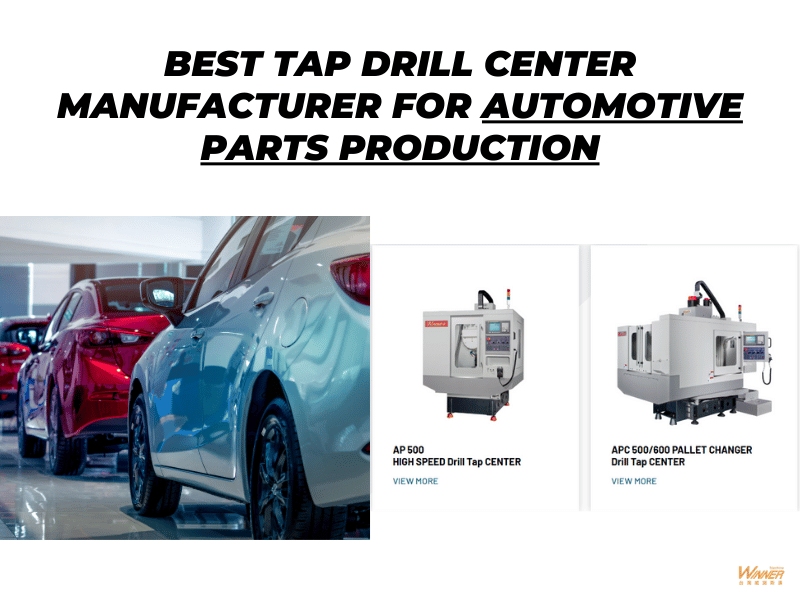

At Taiwan Winnerstech, we offer two robust Tap Drill Center models built for automotive part machining:

AP500 – High-Speed Drill Tap Center

The AP Series is designed with a high-rigidity structure ideal for powerful cutting, whether it's milling, boring, or side cutting. Equipped with a high-speed spindle, rapid feed axis, and advanced acceleration/deceleration control, the AP series ensures fast cycle times and optimal production efficiency. This makes it particularly well-suited for processing various car and motorcycle parts that require contour machining, multi-facet drilling, and small-diameter hole tapping—especially on aluminum or cast iron materials.

APC 500/600 – Drill Tap Center with Pallet Changer

For even greater production efficiency, the APC Series integrates a pallet-changing mechanism, enabling non-stop machining. While one workpiece is being processed, another can be set up, dramatically reducing idle time. Like the AP Series, the APC 500/600 models excel in high-speed drilling and tapping of complex parts. They are widely used in the automotive sector for mass production of engine, brake, and transmission parts, while also supporting 3C and electronics applications due to their ultra-finishing capabilities.

Both series offer:

- High-speed ATC for tool changes

- Stable multi-axis coordination for complex geometries

- Excellent chip evacuation and cooling systems

- Synchronous control for reduced pallet change downtime (APC Series)

Built for the Demands of the Automotive Industry

Winnerstech's Tap Drill Centers are built with the needs of auto parts manufacturers in mind. Whether you're producing aluminum transmission housings, cast iron engine blocks, or precision brake system components, our machines deliver the high output, repeatable accuracy, and durability your production lines demand.

Our machines have been successfully applied in:

- Multi-hole tapping on engine and brake system parts

- Drilling and deburring on transmission casings

- Precision tapping of small-diameter holes in aluminum components

- Mass production workflows requiring minimal downtime

Why Choose Taiwan Winnerstech?

As a leading tap drill center manufacturer, Taiwan Winnerstech combines decades of CNC expertise with a focus on innovation and real-world application. Our machines are not only built for speed and precision—they're built for long-term reliability, serviceability, and integration with your existing production systems.

We provide:

- Customizable solutions based on your parts and materials

- Responsive technical support

- High-efficiency models tailored for the automotive sector

Ready to Upgrade Your Machining Line?

If you're in the automotive industry and looking for a tap drill center that delivers speed, stability, and exceptional value, explore the AP and APC Series from Taiwan Winnerstech. Contact us today to discuss your production requirements and learn how our solutions can help you achieve higher precision with lower costs.