Solutions

Parts Processing

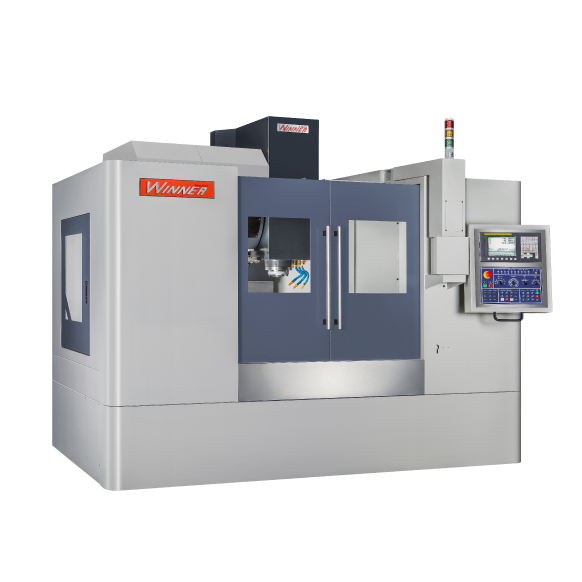

In recent years, many companies have adopted CNC machine tools to engage in high-precision manufacturing and processing in a cost-effective manner. The most important consideration in the metal processing industry is to use network monitoring technology and simulate the product drawings that need to be processed in advance and test them first before going into production. Such "preliminary testing" can reduce time wasted in initial exploration (to achieve compliance product/accuracy goals) before officially entering production manufacturing. Therefore, the reduction in production/manufacturing time is equivalent to improving manufacturing efficiency, thereby reducing costs and improving the competitiveness of enterprises.

In the early days, most industries used CNC tools to machine metal products. The application of metal processing parts has expanded to various industrial fields and developed to the manufacturing and processing of composite materials. If we divide it by product, there are hand tools, auto parts, mechanical appliances, household products, etc., all of which require CNC machine tools.

In addition, the increasingly serious labor shortage has also prompted processing companies to further increase the demand and application of automated machinery. In the future, in addition to the demand in the existing market, the introduction of automation, emerging markets, and the growing demand for more efficient manufacturing technologies will further drive the demand for the metal processing market.