Solutions

Mold Making

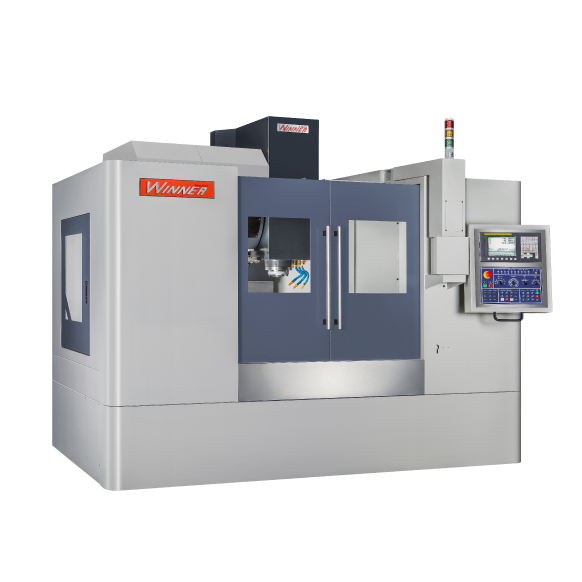

The manufacturing and processing of molds need to reach a certain level of precision, stiffness and service life to ensure the quantity and quality of mold products. In this field, CNC machines are definitely the leader and have indispensable strength.

Mold numerical control (CNC) processing machines can achieve high-precision, high-speed, high flexibility, networked and intelligent mold processing technology. Mold processing equipment using advanced numerical control (CNC) processing machines can complete single-piece, small-batch, high-precision and complex-surface parts processing.

At present, the accuracy of CNC machining technology can well guarantee the accuracy of molds. High-speed cutting can increase the cutting force during processing, reduce thermal deformation during processing, and increase processing speed. Flexible processing can achieve multi-size, multi-deformation, and wider range of mold shape processing.

Numerical control (CNC) processing machines, through intelligent processing, can not only realize remote processing monitoring, control, detection and diagnosis. Intelligent processing technology can realize self-testing, automatic programming and integration of expert systems of processing equipment, providing maximum convenience for processing mold processing and precision mold manufacturing.