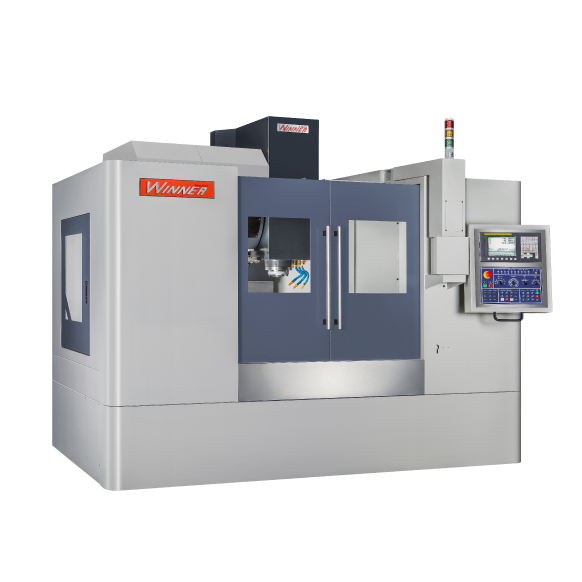

VMC E 1300 / 1400

COMBINED GUIDEWAYS Vertical Machining Center

Features

- PRECISION VERTICAL MACHINING CENTER

- MODEL VMC VMC E 1300 / 1400

- VMC E1300 – X-Y-Z travel by 1300/650/650mm

- VMC E1400 - X-Y-Z travel by 1400/700/700mm

- 20HP spindle output

- 20 M/min. rapid feed rate (E series)

- Wide base weights 2.6 tons provide extra rigidity

- Z-boxway; X-Y linear guideways/ 4-guideways on Y-axis

Product Detail

The VMC E1300/E1400 models in our Combined Guideways series are renowned for their robust construction and design excellence. The entire series features a bend-resistant reinforced base, with columns that incorporate a long-span box-shaped structure. This design is enhanced with an internal cross-rib structure, providing exceptional rigidity and stability essential for heavy-duty cutting operations. The ability of these machines to minimize thermal deformation under intense operational conditions is a testament to their advanced engineering.

Global recognition of the VMC E1300/E1400 stems from several key factors. The integration of a high-efficiency motor and an outstanding PLC control system contributes significantly to the machine's superior controllability. This allows for precise management of the three-axis rapid displacement, ensuring smooth and accurate machining even during complex operations. The strong structural foundation of the VMC E1300/E1400 not only supports rigorous tasks but also enhances overall machining precision, making these models a preferred choice in industries where reliability and precision are paramount.

Specifications

| MODEL: VMC E 1300 / E 1400 | |||

|---|---|---|---|

| WORKING TABLE | |||

| Working table szie | mm | 1500 x 710 | |

| T - slots | mm | 18 x 7 x 100 | |

| Max. table load | kgs | 1000 - 1200 | |

| TRAVEL | |||

| X axis travel | mm | 1300 / 1400 | |

| Y axis travel | mm | 650 / 700 | |

| Z axis travel | mm | 650 / 700 | |

| Spindle nose to table surface | mm | 120 - 720 | |

| SPINDLE | |||

| Transmission | set | Belt - Drive (STD) ; Direct - Drive (OPT) | |

| Spindle taper | set | BT - 40 | |

| Spindle speed | rpm | 8000 (Belt) | |

| Spindle motor | kw | 11 / 15 | |

| FEED | |||

| X-Y-Z motor output (Fanuc) | kw | 3 / 3 / 4 | |

| X-Y-Z motor output (Mitsubishi) | kw | 3.5 / 3.5 / 3.5 | |

| X-Y-Z rapid travel | M/min. | 20 / 20 / 20 | |

| X-Y-Z cutting feed rate | M/min. | 10 | |

| ATC SYSTEM | |||

| ATC type | set | Arm type (STD) | |

| Magazine capacity | nos. | 24 | |

| Max. tool diameter | Φ(mm) | 100 | |

| Max. tool length | mm | 300 | |

| Max. tool weight | kgs | 10 | |

| RAIL TYPE | |||

| E series | set | Z boxway / X-Y linearway | |

| DIMENSION & OTHERS | |||

| Power comsumption | KVA | 25 | |

| Air pressure required | kg/cm² | 6 - 8 | |

| Floor occupation (LxWxH) | cm | 385 x 350 x 270 | |

| Machine weights | kgs | 8500 | |

All Specifications&Design Are Subject To Change Without Prior

Option

- 1. Rigid tapping

- 2. RS-232 interface

- 3. Auto power off

- 4. 3-axes auto lubrication

- 5. Alarm indicator

- 6. Cooling device

- 7. Spindle air blast

- 8. Heat exchanger

- 9. Working lamp

- 10. Coil conveyor (L/R)

- 11. Remote hand wheel

- 12. Full guarding enclosure

- 13. Telescopic cover on 3-axes

- 14. LED light (inside m/c)

- 15. Operation & maintenance manual

- 16. Tool kits & foot pad screws